3. Probiotics Probiotics help maintain a healthy gut and can support the urinary tract by promoting beneficial bacteria. Using a dog-specific probiotic supplement may contribute to overall urinary health, but it should not replace veterinary treatment for an active infection.

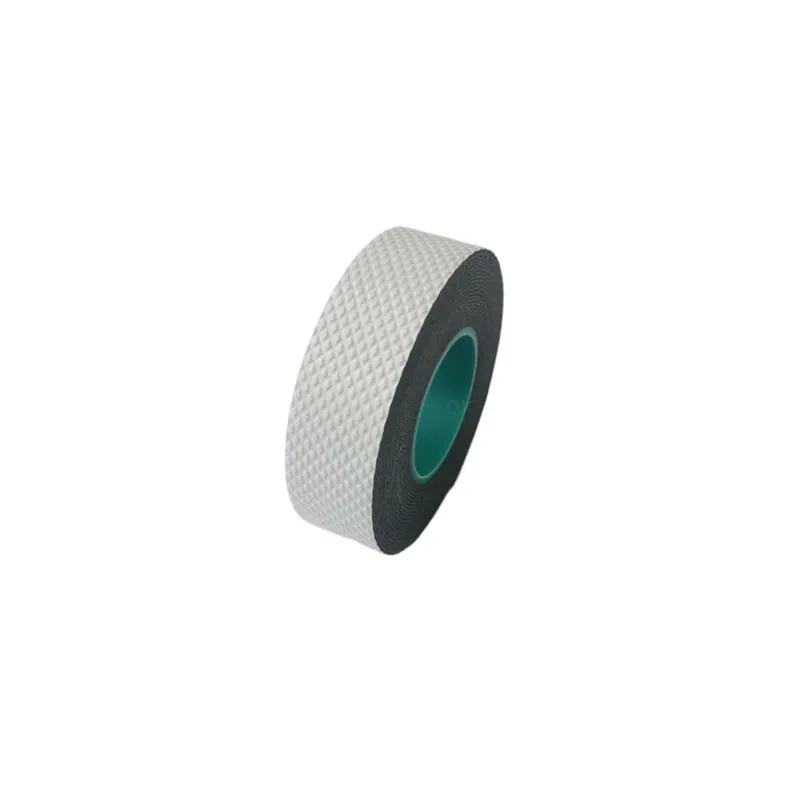

Then, starting at one end, wrap the tape tightly around the wire or surface, overlapping each layer by half its width to ensure complete coverage Then, starting at one end, wrap the tape tightly around the wire or surface, overlapping each layer by half its width to ensure complete coverage

Then, starting at one end, wrap the tape tightly around the wire or surface, overlapping each layer by half its width to ensure complete coverage Then, starting at one end, wrap the tape tightly around the wire or surface, overlapping each layer by half its width to ensure complete coverage